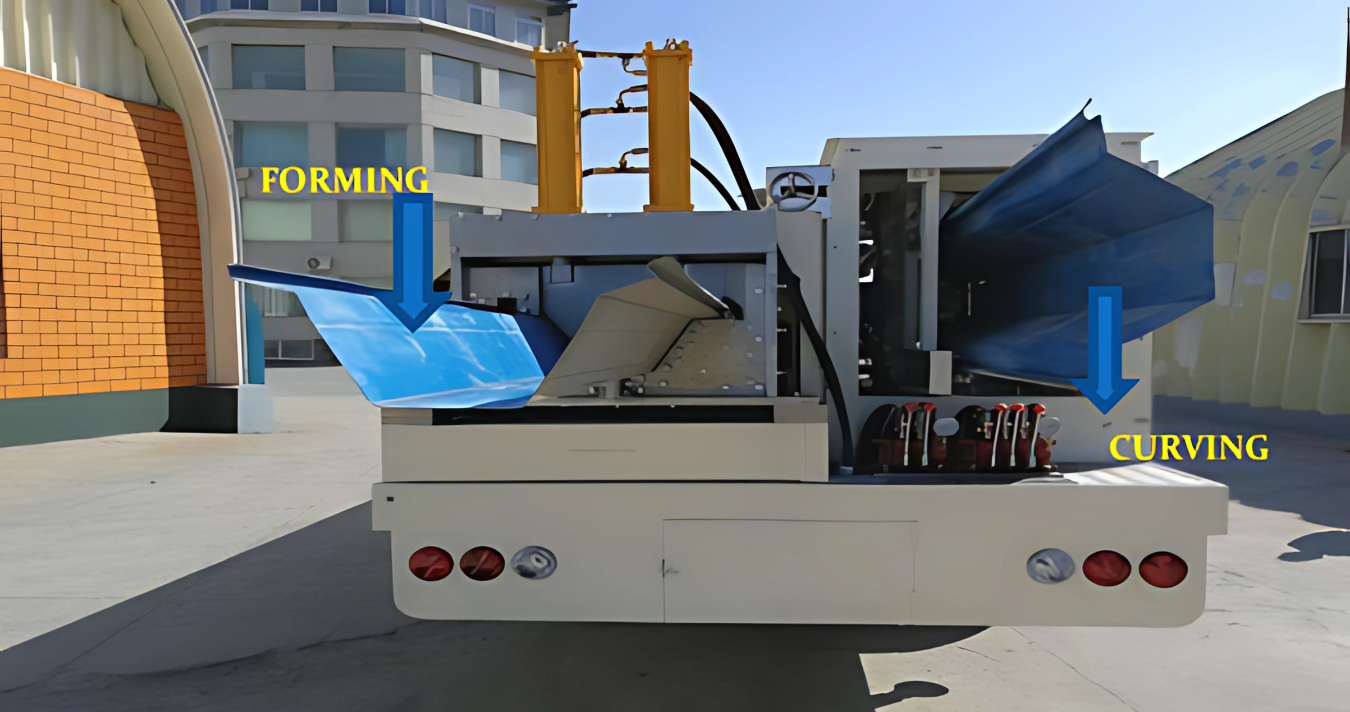

Description

Leak-proof roofing ensures durable protection by preventing water seepage through seamless designs and strong sealants. In such systems, sanding seams play a crucial role by preparing metal joints for effective adhesion of sealants and coatings. The process removes debris, smooths sharp edges, and enhances surface bonding, ensuring a tighter seal. This preparation improves corrosion resistance, extends coating longevity, and guarantees a flawless, leak-free finish for durable and reliable roofing systems.

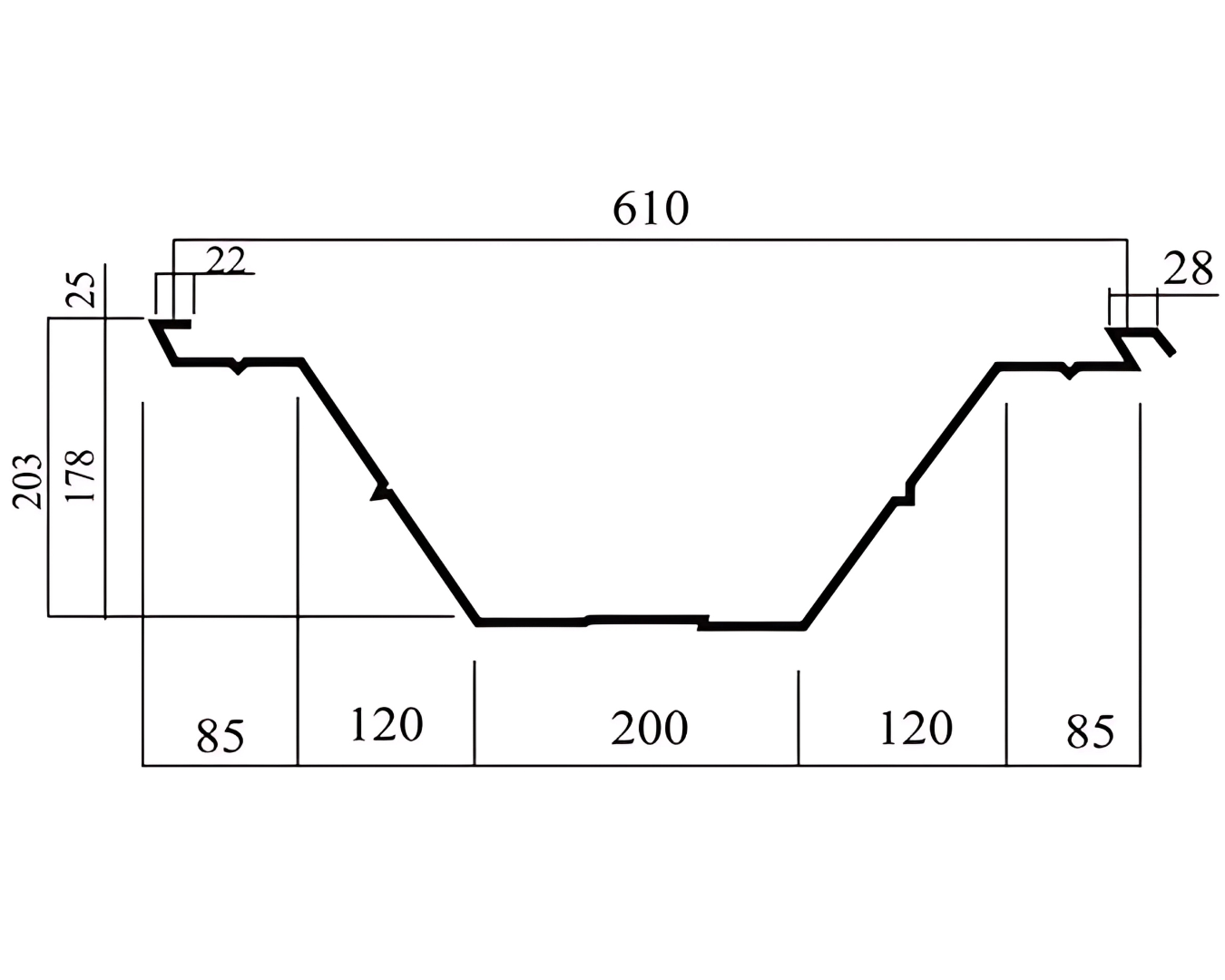

| Type | Base Material | Thickness (mm) |

|---|---|---|

| Panel | Color Coated/GA | 0.8 - 1.2 |

Sanding Seam

Sanding Seam is a roofing and construction process that prepares metal surfaces or joints

for better adhesion, a smoother finish, and improved durability. By smoothing or roughing up

overlapping metal seams, it ensures enhanced sealant bonding, removes sharp edges, prevents

corrosion, and provides a professional aesthetic. The process involves cleaning the surface,

sanding with appropriate grit, removing dust, inspecting for uniformity, and applying

sealants or coatings. Essential tools include sandpaper, mechanical sanders, cleaning

brushes, and protective gear. This technique is crucial in trussless roofing systems for

effective sealing, leak prevention, and extending the lifespan of coatings and protective

layers.

The Sanding Seam process is essential in roofing and construction for preparing metal

surfaces or joints to ensure better adhesion, smoother finishes, and long-lasting

durability. It involves cleaning the surface to remove dirt and grease, sanding the seams

with appropriate grit to smooth or roughen them, and eliminating dust to prevent

contamination. This process enhances the bonding strength of sealants, removes sharp edges,

and prevents corrosion at the seams. Finally, sealants or coatings are applied to create a

durable and aesthetically pleasing finish. Sanding Seam is particularly crucial in trussless

roofing systems to ensure effective sealing, leak prevention, and extended longevity of

protective layers.

- Enhances bonding strength of sealants.

- Smooths sharp edges and irregularities.

- Prevents early corrosion at seams.

- Improves the longevity of protective coatings.

- Provides a professional finish.