COLOUR COATED ROOFING SHEET

“SKY IS THE LIMIT FOR PRE COATED SHEET” Coated Steel Sheet has been used extensively by the construction industry throughout the World for nearly two centuries. Because of its excellent corrosion resistance, it has become the preferred product for a wide range of construction uses, particularly roofing and walling. Coated steel sheet is a unique building material. It combines the strength of steel with the excellent corrosion protection of zinc/aluminum alloy coatings. It can be punched, roll-formed and joined into a limitless number of structural and decorative building products.

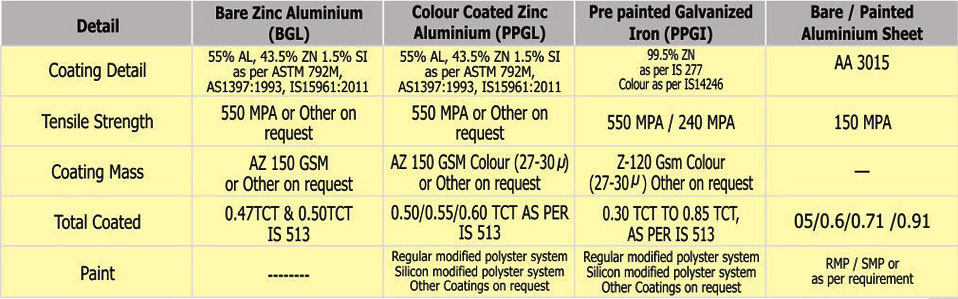

TECHNICAL SPECIFICATIONS OF ALUMINUM ZINC ALLOY COATED STEELS

| BASE METAL | High tensile steel |

| COATING MASS | AZ150 |

| COATED STD. | AS1397-1993 |

| YIELD STRENGTH | 550Mpa/300Mpa |

| THICKNESS | 0.50mm |

TECHNICAL SPECIFICATION OF GALVANISED COLOR COATED STEEL

| BASE METAL | High tensile steel |

| COATING MASS | 120 GSM |

| COATED STD | IS: 277/JIS:3302 |

| YIELD STRENGTH | 240MPa |

| THICKNESS | 0.50mm &.6mm |

| TOLERANCE | +/-0.03 |

ADVANTAGES:

Excellent design & secure fastening systems ensure the security and weather-light performance of coated steel roofing during extreme weather. Coated steel sheets are resistant to fire and no water leakage.

Excellent thermal properties that keep the building cooler in summer and warmer in winter.

Prevents noise and provide a quite roofing system, particularly when used in combination with appropriate insulation systems

We can customize the color & other parameters of the galvanized roofing sheets based on client´s requirement. Our company is involved in providing end to end solutions with regard to roofing sheets like designing, manufacturing, installing and completing the setup to meet the fullest satisfaction of the customer.

We supply corrosion resistant Roofing Sheets in the below finish:

- Al-Zn Alloy Coating: The Al-Zn Alloy Coated Steel Roof Sheet we supply is popularly known as Bare Galvalume Roof Sheet.

- Pre Painted & Galvanized: Swathi Build Tech Pvt Ltd manufacture best quality Pre Painted Galvanized Steel Roofing Sheet is also known as PPGI Roofing Sheet.

- Color Coated: At SWATHI we supply Color Coated Al-Zn Alloy Roof Sheets, which is also called as Color Coated Galvanized Roof Sheet.

At Swathi Build Tech we supply:

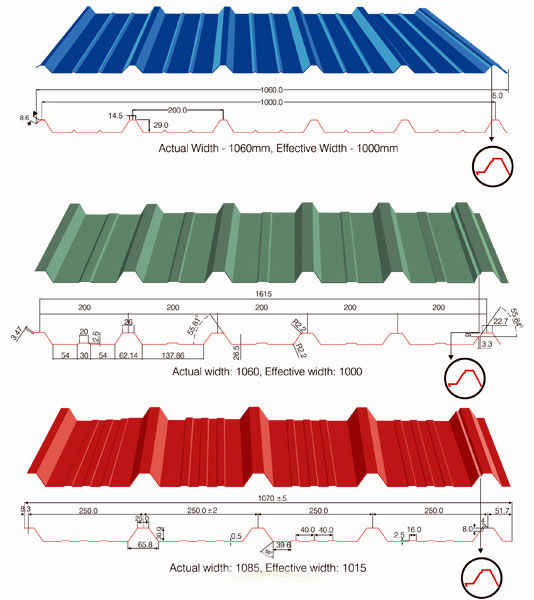

- Corrugated Roofing Sheet

- Box Profile Roofing Sheets

- Tile Effect Roofing Sheets

- Curved Roofing Sheets

Why should you buy from Swathi Build Tech??

We offer roofing sheets in a variety of Colors

- At SBT we use the latest technology and through advanced machines to make a precision engineered Color Coated Roofing

- The in-house Quality Team ensures that the best product is delivered at each stage of production

- Our roofing sheets require the least maintenance & will serve a long life

- The Color Roof sheets are priced competitively

- Our raw material supplier is mainly JSW for which we have entered an MOU with them. Which proves the Genuine and original product.

- ISO 9001-2008 CERTIFIED

- Also approved by IOCL for false ceiling & clip lock roofing.

Salient features of our profile :

- Best balance between coverage and strength

- High ribbed profile for better support on longer spans

- High trapezoidal crest for adequate drainage and aesthetic appeal

- Hexagonal trapezoid for best load distribution

- Anti capillary groove to ensure zero leakage as a result of capillary action

- Scientific design for usage in high wind load areas also

- Suitable for Roofing/ Cladding/ Barricading and other applications

Application:

Right Product for right Applications:

- Choose correct material/thickness/profile/coating for all application

- Thickness: 0.5mm TCT for general use, for long spans, use higher thickness

- Bansal 1000 Profile suited to handle most applications, only under very special requirement of very high wind loads(severe cyclone areas only) we recommend higher corrugation profiles

- Where interlocking formation is needed we recommend softer material like normal PPGI / PPAL

Handling and Storage :

If PPGI/PPGL/PPAL products are to be stored for any time prior to forming or installation, they must be stored in dry, well-ventilated conditions. Storage which allows water (including condensation) to be trapped between the sheets may damage the coating beyond repair.

Pre-painted steel products must be handled carefully during transport, fabrication and fixing to avoid damaging the surface.

Handling :

General

- SBT products are top quality and perform best when handled correctly.

- Don’t handle them roughly or carelessly.

- Don’t drag or slide new sheets over other products or rough surfaces.

- All equipment and materials taken on to the roof should be clean and care taken to prevent damaging the surface.

Use of Lifting Booms

- Long lengths of roofing are best lifted with the aid of a lifting boom.

- Lifting booms may be available from the profile manufacturer.

- Ensure loads are secure prior to lifting.

Footwear

- Anyone walking on the roof should wear flat rubber-soled footwear to prevent marking.

- Put an old mat or piece of carpet at the base of the ladder so that shoes can be cleaned before going up on the roof.

- Care should be taken walking on roofs as they may be slippery at times

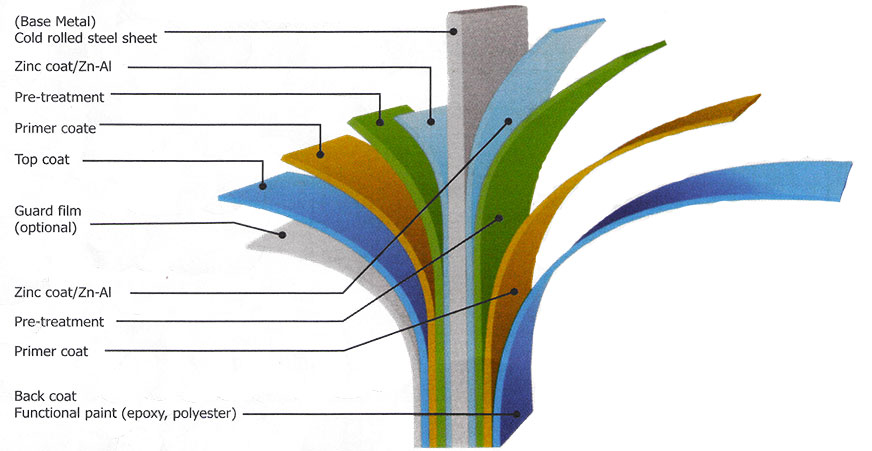

Strippable Guard film :

The strippable film is applied to some pre-painted steel products on request of the customer to protect them during transportation and roll forming. Where present, strippable film normally remains on the pre-painted steel product through roll-forming, transportation, and installation but should be removed within a maximum of two weeks after fixing.

If allowed to remain on pre-painted steel for an extended period, strippable film can be difficult to remove, especially when the effects of exposure make the film brittle.

Leaving the film on for extended periods may also damage the sheet by inhibiting dust in the crevasse near the edge or where ever there is a tear in the film.

Storage:

- Before it goes up on a roof pre-painted steel/Aluminum products can be ruined by poor storage practices.

- Follow these simple guidelines to help give optimum performance.

- On arrival, ensure the steel sheets are dry. If wet, open the pack immediately and separate the sheets to allow them to dry.

- Store packs of the material off the ground in a sheltered position.

- Cover packs with a loose fitting tarpaulin, allowing air to circulate.

- Provide some fall to drain water.

- Cross-stacking of sheets allows air to circulate to help keep material in prime condition.

- Use only dry, untreated timber fillets for block stacking.

- Contact with wet concrete should be avoided.

- Note: Failure to follow these handling and storage precautions could result in spoiling the surface appearance of the products and severely reducing their service life. On PPGI/PPGL material this will could be a bubbling of the paint surface/appearance of white rust at edges/peeling/etc.. Damage resulting from such failure invalidates the warranty and is not recoverable from SBT

Do’s and Don’ts of Handling of Colour Coated Sheet

Dos of Fixing

- Do check the delivery to make sure you have the right product, delivered in prime condition.

- Do arrange for suitable dry storage if the material is not going to be used immediately.

- Do ensure the appropriate fasteners are selected for the environment.

- Do cut with shears or snips.

- Do remove swart from the job as the work progresses, or at least at the end of each day.

- Do wear clean, flat, rubber-soled footwear.

- Do lift sheets onto the job, rather than drag them.

- Strictly avoid surface abrasion by walking/rubbing/dragging etc. over the coated area. It will damage the coating.

Dont’s of fixing

- Don’t cut sheets with an abrasive disc cutter.

- Don’t attempt to solder pre-painted steel surfaces.

- Don’t use lead-headed nails.

- Don’t use touch-up paints unless recommended by our experts.

- Don’t leave off-cuts of other debris on the roof.

- Don’t keep sheets bundle exposed to water/moisture.

WATER PONDING :

- Roofs:

- Where the roof pitch is low, changes in roof loadings may result in a negative pitch and consequently lead to water ponding. Water ponding is detrimental to the performance of prepainted steel products. The following conditions commonly cause water ponding.

- Over-spaced purlins.

- Deformation of timber purlins.

- Placement of external loads such as air conditioning units.

- Rigid fixing on long spans which causes deformation of the profile as a result of thermal expansion.

- Design Guide:

- Never use a pitch of less than 3 degrees. Pitches of less than 3 degrees invalidate the warranty.

- Design the roof according to the profile manufacturer’s specifications.

- On minimum pitch roofs, ensure that the gutter end of profiled sheets is turned down.

- Allow for thermal expansion to prevent profile distortion.

- Consider the use of walkways to prevent damage where the roof may be subject to heavy foot traffic.

- Ensure roof penetrations do not block the flow of water from the roof.